The fuel efficiency of an internal combustion engine (ICE) is significantly determined by its thermal efficiency and the fuel density¹ — independent of the type of fuel the thermal density dominates. There’s other fuel efficiency factors such as the following some which either have a minor effect or are already practically nearly fully optimized:

- friction of moving parts

- inefficient combustion

- heat loss from the combustion chamber

- departure of the working fluid from the thermodynamic properties of an ideal gas

- aerodynamic drag of air moving through the engine

- energy used by auxiliary equipment like oil and water pumps.

- inefficient compressors and turbines

- imperfect valve timing

And this is only accounting for the fuel efficiency of the engine and not other factors which also impact the fuel efficiency of the vehicle such as drivetrain (i.e. other rotational mass) losses, aerodynamics and curb weight.

Fuel efficiency doesn’t incorporate other metrics of efficiency such as the power-to-mass ratio of the engine, which might feed into vehicular fuel efficiency via the mass of the vehicle.

The idealized Carnot cycle efficiency for heat engines isn’t attainable because there’s not a perfect, instantaneous combustion¹ and dissipation into the ambient environment — the thermodynamic process isn’t entirely reversible and has irreversible effects that don’t instantaneously return to the nebulous, ethereal (i.e. maximum entropy²) environment. The Otto cycle efficiency models the spark-ignition engine in which the thermal efficiency depends solely on the compression ratio and the specific heat ratio of the air-fuel mixture.

Assuming a specific heat ratio of 1.4 then an increase in the normally aspirated, compression ratio from the typical value of 9 for regular unleaded gas to 13 for 100 to 105 octane E85³ increases the computed Otto cycle efficiency from 58.5% to 64.2%, which is a +10% increase in thermal efficiency and a boost in the power-to-mass ratio. With 113 octane E100³ or race gas, a normally aspirated, compression ratio of 15 to 16 shouldn’t preignite presumably even at optimum timing for maximum brake power, although I’m not clear as to whether that’s requiring a non-fuel efficient, rich fuel-air mixture. Thus increasing the computed model efficiency to 66.2 to 67%, which is a +13% to +15% increase. But E100 requires a more complex distillation process than E95 and isn’t stable as it will rapidly absorb humidity to degrade to E95.

Real world results confirm the 10 to 15% efficiency improvement with E85 notwithstanding the fuel density of E85 having 28% and 32% lower energy content compared to petrol on a volumetric and mass basis respectively. There’s an example of approximately 20% or more fuel efficiency with E85 compared to petrol (again notwithstanding the lower fuel energy density) estimated from brake engine efficiency — which is a measure that incorporates other aforementioned factors that contribute to the inefficiency of an engine.

The conclusion is that for an optimized engine lower concentration ethanol blends can nearly as (and E85 up to 85%) or more as fuel efficient as petrol when including the ethanol’s lower fuel energy density, coupled with the added benefit of increasing engine power and torque. An increase of compression rate from 9 to 16 could increase the horsepower and torque by roughly 15%. Some of that power-density increase could possibly be traded for a leaner fuel mixture to gain more fuel efficiency even if activated only when highway cruising. Given ethanol’s lower heat of evaporation the leaner fuel mixture will run cooler than with petrol.

Turbocharging doesn’t overcome the preignition limitations on fuel efficiency dictated primarily by the octane rating and heat of evaporation of the fuel. Such limits could be maxed out by other means such as increasing the static compression ratio. Turbocharging can trade fuel efficiency for power-density by running a richer fuel-air mixture that supplies more cylinder cooling via the (increased mass of) heat of evaporation. This is why although small displacement, turbocharged engines can be more fuel efficient than normally aspirated, higher displacement, they’re only more fuel efficient when the load requirements don’t demand a level of boost that exceeds the power-density a non-preigniting, optimally fuel efficient fuel-air mixture can provide. Which is a great obfuscation for providing high EPA mileage estimates in highly controlled lab conditions that don’t match real world results. Because of this drivers often notice that their vehicle equipped with a small displacement, turbocharged engine doesn’t have better fuel efficiency than the comparable vehicle equipped with a normally aspirated, higher displacement engine. In other words if one drives their little, shitty micro-engine vehicle as if all the power it had was a normally aspirated micro-engine then they will get fabulous fuel efficiency. The automobile manufacturers are just trying to give us the power and fuel efficiency of a larger engine while fulfilling the necessary virtue-signaling, climate change hysteria political edicts — thus we get crappy turbocharged, micro-engines instead of suitable normally aspirated, larger displacement.

At high enough boost the turbo is adding too much heat and will require an intercooler. An intercooler is only useful to counteract the intake air heating at high boost because it won’t have much effect in terms of lowering the temperature enough to augment the cylinder cooling effect of the fuel mixture’s heat of evaporation.

Turbocharging is thus normally one of several means for trading off increased power-density for some other feature of the engine such as fuel efficiency. Lopey high lift cams increase effective, dynamic displacement and thus also effective, dynamic (c.f. also) compression ratio which increases power-density while typically demanding an overly rich fuel-air mixture, thus reducing fuel efficiency. Whereas, turbocharging doesn’t sacrifice low-end torque and idle smoothness. But effective, dynamic compression ratio, brake efficiency and thus optimum fuel efficiency aren’t constant across the power band, which is why transmissions are adding shift positions (aka speeds) and variable valve timing (VVT) exists to increase the percentage of the time that the engine is run within its optimum efficiency band which isn’t necessarily the same as downspeeding (or always running in) the highest gear.

Turbocharging offers a unique capability (excepting the novel variable compression ratio engine technologies) to provide a much more significant range of effective compression ratio with its wide range of volumetric efficiency. In theory this could be particularly beneficial for creating a Flex Fuel Vehicle (FFV) which is fuel efficiency optimized on the fly for petrol, any blend with ethanol or perhaps even eFuel — while also enabling to sacrifice fuel efficiency via higher boost and rich fuel mixtures for additional power density when needed or desired. And especially appropos for retrofitting normally aspirated petrol engines for said optimized FFV capability. An ethanol vehicle is operating in the range of effective compression ratio for a diesel engine — it may even be possible to run ethanol in a Diesel cycle compression-ignition engine. Brazil’s disaster of optimizing solely for E95 exemplies the benefit of FFVs.

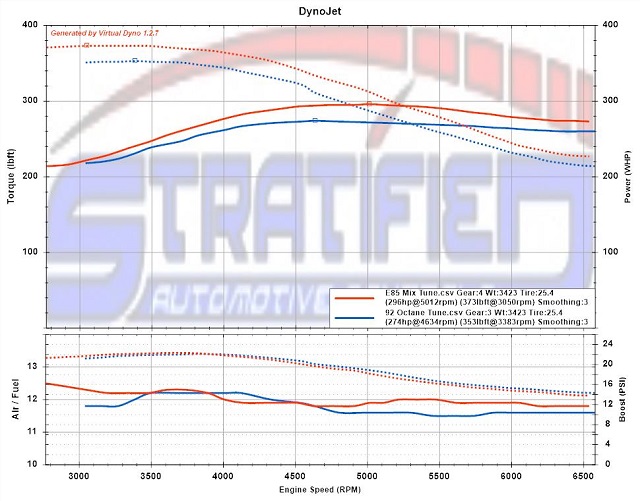

Because of the aforementioned capability to obfuscate the fuel efficiency at the manufacturer’s claimed maximum load power-density (i.e. the lower than published fuel efficiency due to richer fuel mixture at that peak power-density), it’s not possible to determine from the scant published information whether the available FFVs with turbocharging are fully optimized for E85. For example the Ford 3.5L EcoBoost states that there’s no loss of power-density with E85 yet there’s not even any published EPA fuel efficiency rating for E85 such as for the 2010 Ford Taurus SHO. And all recent model Ford EcoBoost vehicles aren’t enabled to run greater than E15 and afaics there’s no available performance and efficiency specifications for that blend. Is there a conspiracy to prevent more autonomous fuels or was this a natural (i.e. free market) move away from turbocharged FFVs for some other reason such as low demand, corrosion of aluminum, climate-change virtue signaling or additional engineering costs? A comparison chart for an aftermarket E30 EcoBoost tune indicates an approximate 7% to 15% increase in horsepower and 5% to 8% increase in torque with roughly the same fuel-air mixture as petrol.

If we assume that’s energy content normalized fuel mixture then the said increase comes with E30’s 8% lower energy content which may or may not be partially or fully offset by an increase in brake efficiency due to the increased power density with no increase in richness of the fuel mixture. If instead the fuel mixture chart isn’t normalized to E30’s reduced energy content then all the cited power density increases are coming with very large increases in fuel efficiency which I think is unlikely.

Ford Bronco enthusiasts discuss tuning for E30 up to E85 without any emphasis on fuel efficiency. Saab optimized an engine for E85 and was able to double the power-density and presumably only when not heavily loaded⁴ gain 10% fuel efficiency (not factoring in the lower fuel energy density). I posted a comment in the Bronco discussion:

Yesterday I wrote Internal Combustion Engine (ICE) Efficiency which links to this discussion thread.

It seems everyone in this thread is more focused on maximizing only power-density and not also fuel efficiency?

I concluded in the linked document that turbocharging can add power-density beyond the fuel efficient sweet spot at the expense of fuel economy by running richer fuel-air mixtures to avoid preignition knocking with higher boost levels.

I also conclude that one of the benefits of turbocharging would be to create optimized FFVs which can maximize fuel efficiency for straight petrol through all range of ethanol blends, while also allowing dynamically exceeding such sweet spots for maximal power-density on-demand by having the computer dynamically adjust the parameters such as fuel-air mixture.

Why are no turbocharged engines fulfilling this capability from the factory? In fact all the U.S. FFVs are non-turbo now, which is just silly as if the industry is trying to give ethanol a bad reputation? Or are they doing this for some other reason such as discouraging the corrosion ethanol can cause?

Apologies in advance if my comment is too late or is too diversionary. I’m hoping it’s perceived as on topic. Cheers.

I didn’t dig too much in direction injection, yet the following comment is worth noting:

Anyway, DI turbos are hampered because direct-injection systems become hugely expensive if they have to work above about 6,500rpm.

I noted:

If bio-ethanol is described as a revolutionary fuel and “clean”, some people think it is not the best alternative ecologically speaking. In theory, the CO2 released during combustion is collected by the plants that will be used to produce ethanol. This fuel can also get rid of some of the energy dependence vis-a-vis the oil-producing countries. Ethanol also allows the development of agricultural land and creating new opportunities for its operators.

In practice, its ecological aspect is questioned a lot mainly because ethanol production contributed to soaring food prices due to the use of food resources for the transportation industry. However, we do not know at what level can be attributed to bio-fuels such increases.

And noted:

E85 critics contend that production of ethanol from corn (maize) drives up world food prices, causing corn to be unaffordable or even unavailable. E85 advocates counter that concern by pointing out that over 93% of all corn grown in the United States is never fed directly to people, but is instead used as livestock feed. Corn used to produce ethanol contains a high amount of starch and is not easily digestible by humans, like sweet corn. American farmers grow more corn than people purchase; there is an annual surplus of corn in the U.S.

Motortrend said:

it takes roughly 30 percent more energy to produce ethanol from corn than it does to make it from sugar cane, and this further dents the global case for corn ethanol as a fuel.

But if most of the world’s ethanol fuel would be produced from sugar, note sugar as food is a chronic toxin (c.f. also, also, also) that humans should be eating much less of.

The only way to bypass the limits of Carnot cycle efficiency is to use a chemical process to create energy without employing heat.

Elon Musk, CEO of battery-electric vehicle [BEV] maker Tesla Motors, stated in 2015 that fuel cells for use in cars will never be commercially viable because of the inefficiency of producing, transporting and storing hydrogen and the flammability of the gas, among other reasons.

Carbon Commentary explained in 2017 that the push for renewables which have volatile generation peaks will drive the demand for the most cost effective storage which he argues will be hydrogen production from water electrolysis:

I try to show that hydrogen production, which is currently almost exclusively carried out by a process using methane and steam, will move to being largely based on the electrolysis of water […] I suggest that hydrogen will become the dominant route to long-term energy storage, not principally as the gas itself but in the form of methane and liquid fuels […] simple economics will drive the oil majors, chemical producers and others towards making fuels from electrolysed hydrogen, rather than natural gas […] In Germany, two thirds of total electricity output at midday on the 7th came from wind and PV. In the UK, gas-fired power stations were throttled back to not much more than 20% of power generation […] The average spot price for power for near-immediate delivery fell to very low levels. Germany saw negative figures overnight and near-zero figures for much of the day […] Very roughly, a new electrolysis plant today delivers energy efficiency of around 80% […] Some manufacturers see electrolyser costs of around £700,000 per megawatt within the next year or so […] As the size of electrolysers sharply increases - we may see 10 megawatt devices soon – the cost per unit of capacity will fall

The conclusion is that large-scale electroysis plants (eventually) running year round would already be producing hydrogen at a capital and operating cost of less than approximately $0.015 per KWh not including input electricity costs including the losses due to 80% efficiency. Year round production will be viable if capex and input electricity costs even at peak load times eventually become less than cost of production of hydrogen from the steaming methane process. Those costs will (have already) be(en) driven down significantly by the convergence of the posited economies-of-scale analgous to the egregious decline in lithium-ion battery costs.

Even if the cost of generated hydrogen from electrolysis doesn’t drop faster than current approximate $0.05 to $0.10 per KWh battery charge cycle due to potential for economies-of-scale in hydrogen to rise more precipitiously, the cost of storage and distribution of hydrogen would need to extremely high to make it cost less than batteries. Electricity also has a capex and operating distribution cost. Tesla’s Powerwall has a 90% roundtrip efficiency contrasted with 60% to 85% for hydrogen fuel cells. The Carnot cycle limited lower efficiency of heat engines probably limits application of eFuels created from hydrogen to extant and ongoing ICEs (including aviation and nautical) for a more emisions (and potentially also cost) optimized, incorrect politically correct (i.e. delusional, anthropogenic-climate-change virtue signaling) compliance option than petrol or clean burning ethanol. Although Musk’s million-mile battery will advance the state of the art, driving battery cycle cost down nomimally faster than the cost of hydrogen generation (because of the latter’s lower current cost), hydrogen storage and distribution costs will decline nominally fast also (because they’re presumably not as low as the production cost) and there’s egregiously insufficient nickel mining to make these advanced lithium batteries ubiquitous. Nickel mining is highly polluting.

Thus regardless whether the available nickel supply is prioritized for some expensive BEVs, hydrogen is the most likely candidate to fill the storage gap in burgeoning demand for electricity storage. Battery driven EVs are significantly heavier (thus reducing fuel efficiency), recharge much slower and have degraded function in cold climates compared to fuel cell EVs (FCEV). The distribution of hydrogen would be aided by the fact that it can be produced from electrolysis with no noxious or odorous emissions close to where it will be used by leveraging the electric grid for input energy contrasted with the noxious, odorous petroleum refineries which are geographically concentrated at crude oil distribution hubs.

Vehicle-to-grid storage is probably not competitive because of the lithium battery charge cycle cost, low efficiency of transporting electricity an additional roundtrip across the grid and EV batteries optimized for weight and volume perhaps at the expense of other efficiencies which might take priority for non-movable storage.

Another potential kick in the pants for Elon Musk could be a new low-cost, solid-state hydrogen storage technology on reusable, recyclable thin-film dialectric that releases the hydrogen with a laser. The fuel weight is less than double of petrol (factoring in tank weight for both) and a third of batteries, with a capex currently at one-fifth the cost of batteries but much longer lifespan because the recycle cost pays for itself due to recovery of deuterium. Perhaps solid-state hydrogen storage and/or LNG fuel tanks would pose less of a fire hazard in accidents compared to lithium batteries.

William commented:

Hydrogen storage would probably be be in polymer tanks at 10000psi. Quite safe, if anything breaks up a tank that strong everyone’s already dead.

Ned Ford commented

So you folks may be ahead of us - more power to you as the old saying goes. Our politics are still a contest between the willing but uninformed and the hopelessly confident but wrong. Somehow we manage to do some pretty smart things anyways.

The slow charging coupled with inability to soon (if ever) scale up the widespread high-energy, rapid charging stations to support ubiquitous adoption for long-distance use, thus relegates BEVs to a predictable duty cycle that allows for slow charging downtime. Significant charging times means (even fast) charging stations will need many more stalls than petrol stations. Heavy duty-cycle commercial use vehicles, transport and machinery (e.g. forklifts) would instead need to employ FCEVs or ICEs, with FCEVs probably only chosen wherein the cost of operation is a significant factor and it plus capex is significantly less than for an ICE. FCEVs are unlikely for any applications where fuel volume is limited and which require extra long range without a recharge of hydrogen, because of of hydrogen’s low volumetric energy content.

BEVs provide autonomy from the petrol refining or (potentially homebrew) ethanol distillation required by ICEs, but most BEV users are tethered to the electric grid. Also BEVs limit long-distance and duty-cycle degrees-of-freedom. Combining that reduction in degrees-of-freedom with BEV’s lithium-ion combustibility, degraded capability in cold climates, accelerated battery aging in extremely hot climates, egregious repair cost if the battery at the bottom of the vehicle is punctured (even if doesn’t burn) and their heavy weight, motivates me to prefer FFVs in spite of an electric motor’s increased energy efficiency, regenerative braking and intense torque over the wide range of RPMs. There’s no BEVs in the lightweight, flickable convertible sports car segment, nor would a non-PHEV BEV be suitable for 4x4 due to heavy weight and need for heavy-duty, steel skid plate on entire underside of the battery. Don’t get me wrong, it might be nifty to have an electric dune buggy analogous to a luxury and/or offroad golf cart for prowling around vicinity of the neighborhood community, especially if the limited range could minimize the battery weight. But it will be a pita if the limited range sometimes caused conflicts in duty-cycle needs.

Thus fully optimized (i.e. turbocharged) FFVs and homebrew ethanol distilleries should be selling like hotcakes if those people who don’t want to be tethered to the grid for BEVs and/or want a lightweight vehicle, were awake to the potential of severe disruption to petrol supplies and the multiple year storage time of sugar as compared to about a year for treated petrol. Ethanol also boosts power-density and has less emissions, with a potentially slight loss of range. It’s not possible to strap on an auxillary energy tank to an EV when embarking on a long offroad trip. Stranded BEVs will not rescued by walking back with a few gallons of electricity. Instead EV owners will fetch a tow truck or a mobile charging station.

Any projections for the imminent demise of ICE vehicles are premature and unrealistic.

Yet EVs (which includes both BEVs and FCEVs) are or eventually will be (even ecosystem holistically) more cost efficient because of the insoluble, low thermal efficiency limit (and the higher TCO including higher maintenance⁵) of heat engines, declining cost of renewable electricity production and declining cost of both lithium-ion batteries and hydrogen technologies. Whereas fossil fuels are becoming more costly to extract (e.g. fracking), non-subsidized ethanol production probably can’t cost compete at global scale and I don’t know if eFuels could lower carbon fuel costs as fast as the factors in the EV economy.

Thus clearly with the onset of the Great Reset then the central-bank-kick-the-can-pretend-so-extended, multidecade debt-bubble, incentivized-to-be-maladapted (thus coming unemployable in the rise of the knowledge age, UBI-dependent) masses are probably headed towards living in Alexandria Ocasio-Cortez’s “built back better” bubble cities tethered to the grid. Of course only after necessarily a Minsky Moment “destroy it first” Great Reset economic devastation. (TODO: link to my re-interpretation of George Friedman’s excellent Storm Before the Calm book)

In summary, BEVs are heavy but claimed lower maintenance and lower TCO (total cost of ownership). Some may think the flat torque curve and acceleration that EVs can provide makes them as or more fun than ICEs, but they can’t any time soon be light and flickable. And they tether us to the grid in ways that my (currently armchair pontification) outdoorsman spirit is offended.

Perhaps I should have named this document “Rise of the electric transport economy and Agenda2030’s Jetsons-like bubble cities”.

From the 28:28 minute mark in the aforelinked Agenda2030 video reminds me to mention the UN/WHO’s pandemic bonds.

- Half-Billion $ Pandemic Derivatives

- “World Health Organization (WHO) to declare the swine flu a global epidemic to fatten their own pockets.”

- “The WHO has a financial incentive in declaring this a pandemic. It issued Pandemic Bonds paying 7% interest which now the WHO does not have to repay.”

¹ The linked article could mislead with, “which means the input temperature and the output temperature are closer.” The Carnot cycle efficiency increases with ratio of the combustion temperature and ambient temperatures, thus their distance and not their closeness. The article is apparently referring to the degree to which the efficiency is equal to the computed Carnot cycle thermal efficiency, “If the temperature of compressed air or air-fuel mixture in a cylinder is the same as the air-fuel combustion temperature, the thermal efficiency is 100 percent.” They also wrote, “Under ideal situations — 100% thermal efficiency — exhaust would be the same temperature as the intake air. That would indicate that all the heat produced during fuel combustion was used to force an engine piston down.” Presumably their “100% efficiency” would equal the computed Carnot cycle efficiency for the specific ratio of combustion and ambient temperatures.

² Idealized as a vacuum.

³ C.f. also.

⁴ Which includes not using a heavy foot on the accelerator pedal. Not heavy loaded in this context refers to keeping the Brake Mean Effective Pressure (BMEP) within the range not requiring levels of boost that demand richer fuel-air mixture higher than the fuel efficiency optimum.

⁵ Even though if an EV needs servicing it will likely cost more, at least until the EV mechanic industry improves.