Blog 2020/10/3

<- previous | index | next ->

I saw these cute little adhesive heat sinks on eBay:

I thought they would be useful for TO-220 form factor parts (commonly used for voltage regulators and transistors).

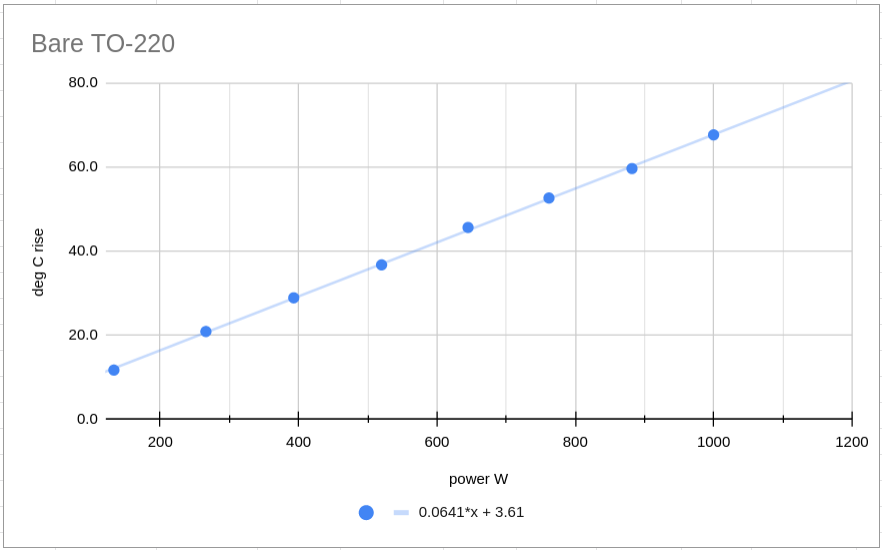

Below are some cooling performance measurements vs a bare TO-220.

If we target a 40C rise in temperature, from the graphs it looks like a bare TO-220 burns about 560mW while the heatsinked part can burn about 800mW at the same temperature. So these little guys give us about a 40% increase in power handling. Not particularly impressive, but a good value for the price (about $0.25 each, which is unusually cheap for a heat sink).

Perhaps an easier to remember take-away would be that a bare TO-220 handles about 1/2 a Watt while the heatsinked TO-220 handles about 3/4 of a Watt.

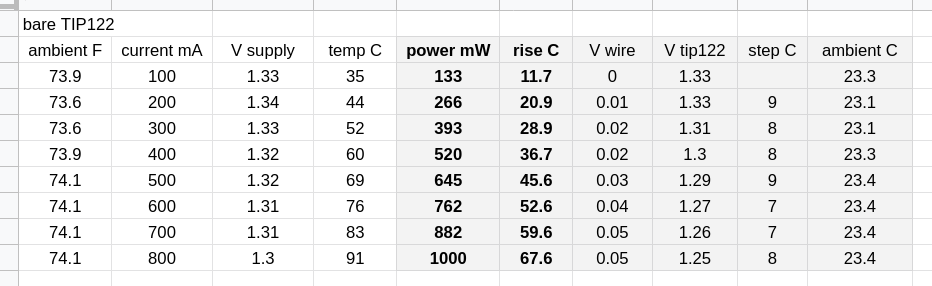

A TIP122 darlington transistor was used as the TO-220 part. The base and collector were soldered together to keep the transistor fully saturated.

The transistor was soldered to two lengths of 24AWG copper wire (a twisted pair from an ethernet cable), approximately a foot in length.

A lab power supply was used in constant-current mode to deliver current in 100mA increments. The lab supply also indicates its output voltage (V supply).

Prior to measuring the parts, the copper wires were shorted (soldered) and the voltage drop (V wire) was measured at each increment of 100mA. This was then subtracted from V supply to derive V tip122.

A type-k thermocouple and handheld multimeter were used to measure the TO-220 case temperature. The thermocouple was clamped to the aluminum tab of the TO-220, with a small dab of heat sink grease applied.

A small temperature and humidity sensor was used to record the ambient temperature ambient F. This was converted to ambient C and then subtracted from temp C to derive rise C.

The current, voltage, thermocouple temperature, ambient temperature, and time were recorded on intervals at least 5 minutes apart. power mW was computed as the product of current mA and V tip122.