Adaptive bed mesh is merged into klipper master branch. You can use this feature without this custom macro. Official klipper adaptive bed mesh

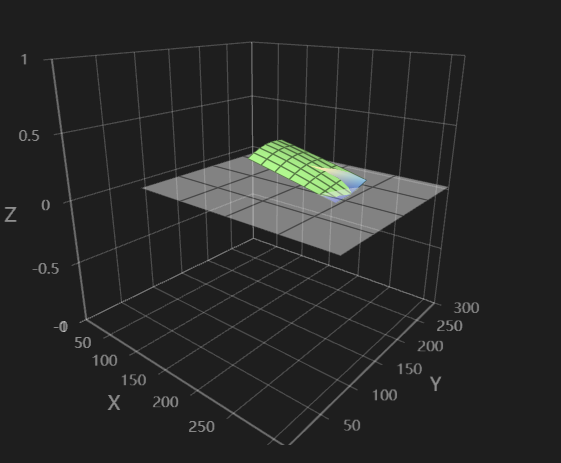

- This macro will dynamically changing the bed mesh area based on the size of the parts will be printed. The fw will only probe on the area that the part will be printed (plus mesh_area_offset value)

- (1) Add the following macro to your printer config, this will replace the default

BED_MESH_CALIBRATEcommand.

[gcode_macro BED_MESH_CALIBRATE]

rename_existing: BED_MESH_CALIBRATE_BASE

; gcode parameters

variable_parameter_AREA_START : 0,0

variable_parameter_AREA_END : 0,0

; the clearance between print area and probe area

variable_mesh_area_offset : 5.0

; number of sample per probe point

variable_probe_samples : 2

; minimum probe count

variable_min_probe_count : 4

; scale up the probe count, should be 1.0 ~ < variable_max_probe_count/variable_min_probe_count

variable_probe_count_scale_factor : 1.0

; enable preference index

variable_enable_reference_index : False

gcode:

{% if params.AREA_START and params.AREA_END %}

{% set bedMeshConfig = printer["configfile"].config["bed_mesh"] %}

{% set safe_min_x = bedMeshConfig.mesh_min.split(",")[0]|float %}

{% set safe_min_y = bedMeshConfig.mesh_min.split(",")[1]|float %}

{% set safe_max_x = bedMeshConfig.mesh_max.split(",")[0]|float %}

{% set safe_max_y = bedMeshConfig.mesh_max.split(",")[1]|float %}

{% set area_min_x = params.AREA_START.split(",")[0]|float %}

{% set area_min_y = params.AREA_START.split(",")[1]|float %}

{% set area_max_x = params.AREA_END.split(",")[0]|float %}

{% set area_max_y = params.AREA_END.split(",")[1]|float %}

{% if bedMeshConfig.probe_count.split(",")|length == 2 %}

{% set meshPointX = bedMeshConfig.probe_count.split(",")[0]|int %}

{% set meshPointY = bedMeshConfig.probe_count.split(",")[1]|int %}

{% else %}

{% set meshPointX = bedMeshConfig.probe_count.split(",")[0]|int %}

{% set meshPointY = bedMeshConfig.probe_count.split(",")[0]|int %}

{% endif %}

{% set meshMaxPointX = meshPointX %}

{% set meshMaxPointY = meshPointY %}

{% if (area_min_x < area_max_x) and (area_min_y < area_max_y) %}

{% if area_min_x - mesh_area_offset >= safe_min_x %}

{% set area_min_x = area_min_x - mesh_area_offset %}

{% else %}

{% set area_min_x = safe_min_x %}

{% endif %}

{% if area_min_y - mesh_area_offset >= safe_min_y %}

{% set area_min_y = area_min_y - mesh_area_offset %}

{% else %}

{% set area_min_y = safe_min_y %}

{% endif %}

{% if area_max_x + mesh_area_offset <= safe_max_x %}

{% set area_max_x = area_max_x + mesh_area_offset %}

{% else %}

{% set area_max_x = safe_max_x %}

{% endif %}

{% if area_max_y + mesh_area_offset <= safe_max_y %}

{% set area_max_y = area_max_y + mesh_area_offset %}

{% else %}

{% set area_max_y = safe_max_y %}

{% endif %}

{% set meshPointX = (meshPointX * (area_max_x - area_min_x) / (safe_max_x - safe_min_x) * probe_count_scale_factor)|round(0)|int %}

{% if meshPointX < min_probe_count %}

{% set meshPointX = min_probe_count %}

{% endif %}

{% if meshPointX > meshMaxPointX %}

{% set meshPointX = meshMaxPointX %}

{% endif %}

{% set meshPointY = (meshPointY * (area_max_y -area_min_y ) / (safe_max_y - safe_min_y) * probe_count_scale_factor )|round(0)|int %}

{% if meshPointY < min_probe_count %}

{% set meshPointY = min_probe_count %}

{% endif %}

{% if meshPointY > meshMaxPointY %}

{% set meshPointY = meshMaxPointY %}

{% endif %}

{% set algorithm = "bicubic" %}

{% if "algorithm" in bedMeshConfig %}

{% set algorithm = bedMeshConfig.algorithm %}

{% endif %}

{% if meshPointX >=7 or meshPointY >=7 %}

{% set algorithm = "bicubic" %}

{% endif %}

{% if enable_reference_index %}

{% set referenceIndex = (meshPointX * meshPointY / 2 - 1 )|round(0)|int %}

BED_MESH_CALIBRATE_BASE mesh_min={area_min_x},{area_min_y} mesh_max={area_max_x},{area_max_y} probe_count={meshPointX},{meshPointY} samples={probe_samples|int} algorithm={algorithm} relative_reference_index={referenceIndex}

{% else %}

BED_MESH_CALIBRATE_BASE mesh_min={area_min_x},{area_min_y} mesh_max={area_max_x},{area_max_y} probe_count={meshPointX},{meshPointY} samples={probe_samples|int} algorithm={algorithm}

{% endif %}

{% else %}

BED_MESH_CALIBRATE_BASE

{% endif %}

{% else %}

BED_MESH_CALIBRATE_BASE

{% endif %}

- (2) Go to slicer setting and replace the old bed mesh gcode the following command.

Prusa Slicer

BED_MESH_CALIBRATE AREA_START={first_layer_print_min[0]},{first_layer_print_min[1]} AREA_END={first_layer_print_max[0]},{first_layer_print_max[1]}

Ideal maker

BED_MESH_CALIBRATE AREA_START={print_pos_min_x},{print_pos_min_y} AREA_END={print_pos_max_x},{print_pos_max_y}

Cura slicer

BED_MESH_CALIBRATE AREA_START=%MINX%,%MINY% AREA_END=%MAXX%,%MAXY%

*(Cura slicer plugin) To make the macro to work in Cura slicer, you need to install the post process plugin click here to download (based on frankbags's script)

- In cura menu Help -> Show configuration folder.

- Copy the python script from the above link in to scripts folder.

- Restart Cura

- In cura menu Extensions -> Post processing -> Modify G-Code and select Klipper print area mesh

- (*) If you use single command start gcode like

START_PRINT BED_TEMP={material_bed_temperature_layer_0} EXTRUDER_TEMP={material_print_temperature_layer_0}.You might need to add parameter parsing to BED_MESH_CALIBRATE inside START_PRINT. This is an example, also check my macro sample

[gcode_macro START_PRINT]

variable_parameter_EXTRUDER_TEMP: 190

variable_parameter_BED_TEMP: 60

; gcode parameters for area bed mesh

variable_parameter_AREA_START : 0,0

variable_parameter_AREA_END : 0,0

gcode:

# preheat, homing, etc

BED_MESH_CALIBRATE AREA_START={params.AREA_START|default("0,0")} AREA_END={params.AREA_END|default("0,0")}

# the rest of your start macro here

And you will need to change Slicer start gcode to this

- Cura:

START_PRINT EXTRUDER_TEMP={material_print_temperature_layer_0} BED_TEMP={material_bed_temperature_layer_0} AREA_START=%MINX%,%MINY% AREA_END=%MAXX%,%MAXY% - Prusa slicer:

START_PRINT EXTRUDER_TEMP=[first_layer_temperature] BED_TEMP=[first_layer_bed_temperature] AREA_START={first_layer_print_min[0]},{first_layer_print_min[1]} AREA_END={first_layer_print_max[0]},{first_layer_print_max[1]}

- 2022/07/21

- Added force lagrange algorithm for mesh with lower than 3 points

- Added

enable_reference_indexconfig flag

- I will try to help if possible, you will have to post ALL of your configs, your slicer start gcode and your sliced gcode.

- If I'm cannot or too slow to respose, our discord members might help you. Check our discord here

Is there any possible way to increase the object area and add a purge line?